HART vs Fieldbus vs Modbus vs Profibus – What is the Difference?

Table of Contents

In the world of process automation and instrumentation, communication protocols act like the languages that connect field instruments with control systems such as DCS (Distributed Control Systems) or PLCs (Programmable Logic Controllers).

Imagine a plant full of transmitters, control valves, sensors, and analyzers. For them to work together smoothly, they need a common “language” to exchange information. That’s where protocols such as HART, Foundation Fieldbus, Modbus, and Profibus come in.

But here is the challenge: No single protocol fits every situation.

Each one has its own strengths, limitations, and best-fit applications. Some are perfect for upgrading old plants, while others shine in new, complex installations.

In this article we will understand the differences in simple terms, so you can understand which protocol works best in which scenario.

So, Lets Start !!

Why Do We Need Communication Protocols in Automation?

Traditionally, plants used 4–20 mA analog signals to send data from field devices to control rooms. While reliable, these analog signals could only transmit one piece of information: the process variable (for example, temperature, pressure, or flow).

But modern plants demand more:

- Device diagnostics

- Remote configuration

- Multi-variable measurements

- Advanced process control

This is where digital communication protocols make a big difference. They carry much more data, support multiple devices, and improve plant efficiency.

Let us now understand the four most common protocols used in the field.

HART (Highway Addressable Remote Transducer)

Type: Hybrid (Analog + Digital) Speed: ~1.2 kbps (slow compared to others) Wiring: Uses existing 2-wire 4–20 mA loop Use: Calibration, configuration, simple diagnostics Best For: Brownfield plants (retrofits)

How It Works

HART combines the traditional analog 4–20 mA signal with a digital signal superimposed on it. This means the control system still receives the analog value, while handheld devices or asset management software can access additional digital data.

Pros

- Uses existing 2-wire cabling, no need to rewire.

- Very simple and widely supported by almost all vendors.

- Perfect for calibration and diagnostics.

Cons

- Slow data speed (~1.2 kbps).

- Not suitable for advanced control or large data exchange.

- Limited scalability (one device per loop).

Real-World Example

An oil refinery wants to upgrade its pressure transmitters for diagnostics without changing miles of old wiring. HART is the best choice because it adds digital access on top of the existing 4–20 mA loops.

Foundation Fieldbus (FF)

Type: Pure Digital protocol Speed: 31.25 kbps (H1 segment) Wiring: 2-wire multi-drop (power + communication on the same pair) Use: Advanced diagnostics, field-level control, multi-device networks Best For: Greenfield projects and complex plants

How It Works

Unlike HART, Fieldbus does not rely on analog signals. It’s completely digital and allows multiple devices to be connected on a single segment. Devices can even perform control functions at the field level, reducing load on the central DCS.

Pros

- Full digital communication with rich diagnostics.

- Multiple devices on a single cable (saves wiring).

- Supports distributed control (smart devices can execute control logic).

Cons

- Requires new infrastructure (not backward-compatible with 4–20 mA).

- Higher cost for installation and training.

- More complex to maintain compared to HART.

Real-World Example

A new petrochemical complex is being designed with thousands of instruments. Since it’s a greenfield project, Fieldbus is ideal — enabling advanced diagnostics, fewer cables, and smart device-level control.

Modbus

Type: Digital, Master–Slave protocol Speed: ~115 kbps (RS-485), higher with Modbus TCP/IP Wiring: RS-232, RS-485 twisted pair, or Ethernet Use: SCADA, PLCs, energy meters, communication gateways Best For: Simple automation, legacy integration

How It Works

Modbus is one of the oldest and most widely used protocols. It follows a simple master–slave structure, where a master (like a PLC or SCADA) requests data and slaves (devices) respond. It works over serial communication (RS-232/RS-485) or Ethernet (Modbus TCP).

Pros

- Very simple and easy to implement.

- Open standard supported by many vendors.

- Flexible – works over both serial and Ethernet.

Cons

- Master–slave means no peer-to-peer communication.

- Limited diagnostics compared to Fieldbus or Profibus.

- Data integrity can be an issue over long distances.

Real-World Example

A water treatment plant uses a SCADA system connected to flow meters and energy meters through Modbus RS-485. It’s cost-effective and works well for this simple application.

Profibus (Process Field Bus)

Type: Digital Fieldbus (developed by Siemens, strong in Europe) Speed:

- Profibus-DP → up to 12 Mbps (fast, for PLC ↔ device)

- Profibus-PA → 31.25 kbps (intrinsically safe, for process instruments) Wiring: DP uses bus cabling; PA uses 2-wire with power Use: PLC/DCS communication, process instruments, drives Best For: Large process plants (especially Siemens-based systems)

How It Works

Profibus comes in two main versions:

- Profibus-DP (Decentralized Peripherals): High-speed communication between PLCs and remote devices.

- Profibus-PA (Process Automation): Lower speed but intrinsically safe, designed for hazardous process industries.

Pros

- High-speed and reliable for industrial use.

- Works well with Siemens PLC/DCS systems.

- Suitable for both factory automation (DP) and process industries (PA).

Cons

- More complex than Modbus.

- Primarily strong in regions or industries with Siemens dominance.

- Cost can be higher compared to simpler protocols.

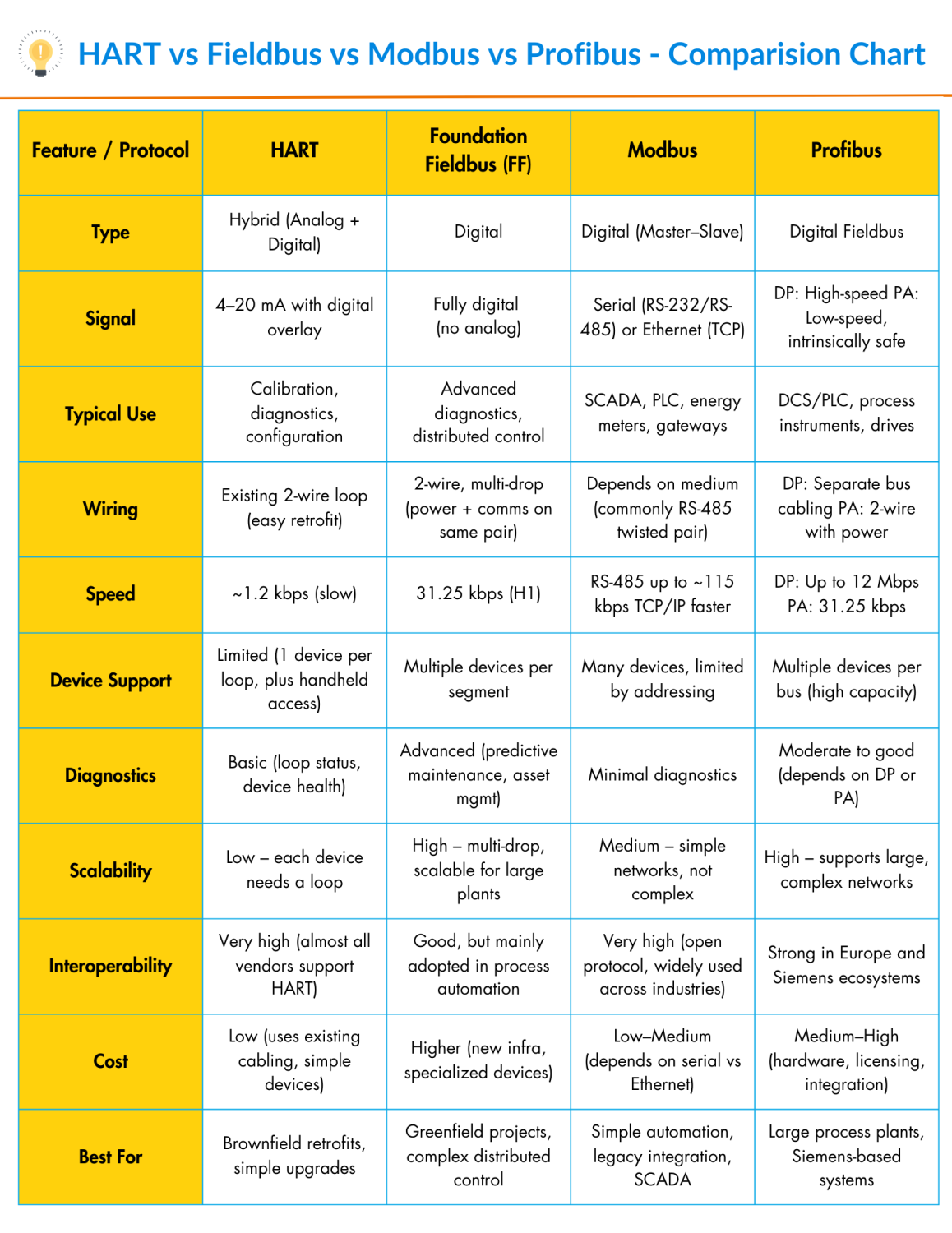

Quick Comparison Chart Comparison Chart

Key Takeaways

- HART → Great for upgrades and retrofits where existing wiring is reused.

- Foundation Fieldbus → Best for modern greenfield plants with advanced diagnostics.

- Modbus → Flexible, simple, and ideal for SCADA and legacy systems.

- Profibus → Reliable choice for large-scale process plants, especially with Siemens systems.

Final Thoughts

There is no “one-size-fits-all” communication protocol in process automation. The choice depends on your project needs:

- Are you upgrading an old plant? → HART.

- Are you building a new, complex system? → Fieldbus.

- Do you need something simple and universal? → Modbus.

- Are you working with Siemens-based process control? → Profibus.

In the end, the goal is the same: reliable communication between field devices and control systems. Choosing the right protocol ensures better efficiency, reduced downtime, and smoother plant operations.

For more information on instrumentation, visit our website or contact our team of experts. We are here to help you find the perfect solution for your flow measurement needs.

“Feel free to share this blog with your colleagues and friends who might find it useful.”