Decoding Coriolis Meter Diagnostics for Reliable Measurement Performance

Table of Contents

- 1 Why Coriolis Meters Are Trusted in Industry

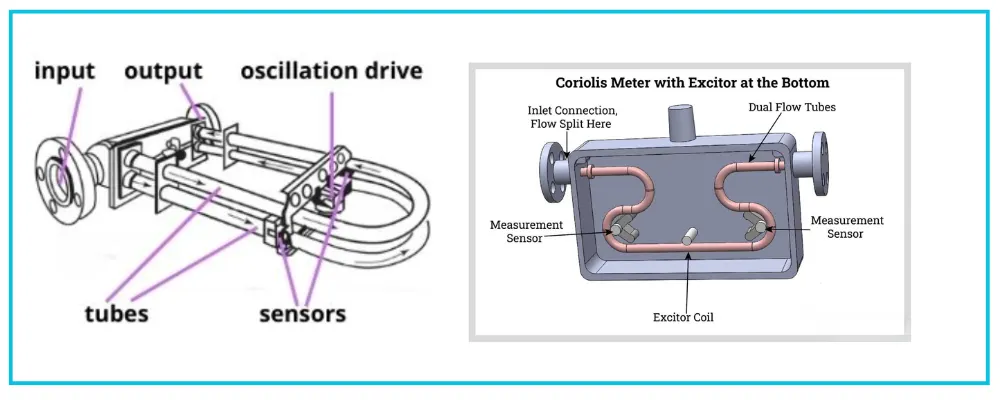

- 2 Beyond the “Black Box” : Understanding Meter Vulnerabilities

- 3 Verification vs Calibration vs Validation – Do You Know the Difference?

- 4 The Heart of Verification – Tube Stiffness

- 5 Understanding Frequency Response

- 6 Process Diagnostics – Detecting Multiphase Flow and Upsets

- 7 Industry Benefits

- 8 From Instrument to Smart Asset

- 9 Common Questions

- 10 Summary:

3 Views